In the dynamic world of industrial manufacturing, ensuring the safety of electrical systems is paramount. One crucial aspect that demands our attention is the issue of Electrical Leakage Protection. This article delves into the intricacies of this concern, shedding light on its significance and exploring practical solutions to safeguard manufacturing operations.

“Safety is not just a priority; it’s a responsibility we owe to our workers and the integrity of our manufacturing processes.”

Understanding Electrical Leakage

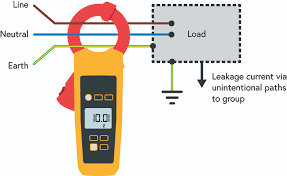

Electrical leakage occurs when an unwanted flow of electric current escapes from the intended path. In simpler terms, it’s like water leaking from a pipe – something we don’t want to happen. In an industrial setting, this leakage can lead to various complications, posing risks to both personnel and machinery.

The Hidden Dangers

- Equipment Damage: Unchecked electrical leakage can damage vital machinery, leading to costly repairs and downtime.

- Fire Hazard: Excessive leakage increases the risk of electrical fires, jeopardizing the entire manufacturing facility.

- Employee Safety: Electrical shocks due to leakage can pose a severe threat to the safety of workers on the shop floor.

Identifying the Culprits: Causes of Electrical Leakage

To effectively combat electrical leakage, it’s crucial to understand its root causes. Let’s break down some common culprits:

1. Insulation Breakdown

In simple terms, insulation acts like a protective cover for wires. When this cover breaks down, electrical leakage can occur. Regular checks and prompt replacement of worn-out insulation are essential.

2. Moisture Intrusion

Water and electricity don’t mix well. Moisture entering electrical components can lead to leakage. Weatherproofing and proper maintenance play a key role in preventing this issue.

3. Poor Wiring Practices

Sometimes, it boils down to how the wires are connected. Faulty wiring or incorrect installations can contribute to electrical leakage. Following proper wiring standards is a fundamental step in prevention.

Protective Measures: Safeguarding Against Electrical Leakage

Now that we’ve identified the challenges, let’s explore effective measures to protect industrial manufacturing processes.

1. Ground Fault Circuit Interrupters (GFCIs)

GFCIs act as watchdogs, instantly cutting off power when they detect a leakage. Installing GFCIs at key points in the electrical system adds an extra layer of protection.

2. Regular Inspections and Maintenance

A proactive approach is crucial. Regular inspections, coupled with timely maintenance, can nip potential issues in the bud. This includes checking insulation integrity and ensuring all connections are secure.

3. Employee Training

Knowledge is power. Educating employees on electrical safety practices equips them to identify and report potential leakage issues. Quick reporting can prevent minor concerns from escalating.

The Role of Technology: Advanced Solutions

In our tech-driven era, innovative solutions are at our disposal to tackle electrical leakage more efficiently.

1. Smart Sensors and Monitoring Systems

Deploying smart sensors that continuously monitor electrical systems can provide real-time data on any irregularities. This allows for swift intervention before a minor issue becomes a major problem.

2. Remote Shutdown Systems

In cases of detected leakage, having the ability to remotely shut down specific sections of the electrical system adds an extra layer of control, minimizing potential damage.

Practical Application

Imagine a bustling industrial factory where machines hum with productivity. In this setting, our focus is on preventing electrical leakage to ensure a smooth and safe operation. Let’s say a diligent worker notices a frayed wire during routine checks. Thanks to their training, they report it promptly. This timely intervention prevents electrical leakage, avoiding potential equipment damage and ensuring the safety of everyone on the shop floor.

Real-world Impact

Consider a scenario where electrical leakage goes unnoticed. A small fault in insulation escalates, leading to a significant leak. Without proper protection, this can result in a sudden machine breakdown, causing delays in production. Moreover, the increased risk of fire poses a threat to the entire manufacturing facility. By addressing electrical leakage proactively, we not only prevent such disruptions but also create a safer working environment.

“In the realm of industrial manufacturing, a small preventive step today ensures a seamless and secure operation tomorrow.”

Conclusion: A Secure Future for Industrial Manufacturing

In conclusion, addressing the Electrical Leakage Protection n issue is not just a matter of compliance; it’s an investment in the safety and longevity of industrial manufacturing processes. By understanding the causes, implementing protective measures, and embracing technological advancements, we pave the way for a more secure and efficient future.

As we navigate the complexities of industrial manufacturing, let us prioritize safety, ensuring that every switch, wire, and connection contributes to a thriving and secure workplace. After all, in the realm of electrical systems, prevention is not just better but imperative.

Allen Bradley – The Brand of Automation

Allen Bradley is a Very famous brand in the industrial automation area, offering a diverse range of high-quality equipment and software for manufacturing. Allen Bradley Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), Variable Frequency Drives (VFDs), Safety Products, Motion Control Products, Control Components and Industrial Network Products are available in the market. Automotive, oil and…

Industrial Automation and Types

Minimize human interference and optimize product quantity and quality with Automation. Explore fixed, programmable, and flexible types

DCS : Distributed Control Systems

The world of Distributed Control Systems (DCS) in industrial manufacturing. How DCS Increases efficiency and ensures safety. A game-changer for production.

SCADA Systems in Manufacturing

“Explore the world of SCADA systems in industrial manufacturing. These superheroes oversee processes, prevent disasters, and boost efficiency seamlessly.

Industrial Communication Protocols

Industrial Communication Protocols make machines work together, shaping a seamless and efficient production process. The amazing talks as machines and bots.

Siemens PLC Systems