In today’s world, where machines and technology are advancing rapidly, the concept of Industrial Automation is gaining prominence in the field of Industrial Manufacturing. Let’s delve into the simplicity of what this means and uncover the significant advantages it brings to the manufacturing landscape.

“The real-world impact of industrial automation goes beyond productivity; it’s about creating safer and sustainable workplaces.”

Understanding Industrial Automation

In straightforward terms, Industrial Automation refers to using smart technology and machines to handle tasks traditionally done by humans. These tasks can range from simple repetitive actions to more complex processes in manufacturing settings.

Streamlining Processes for Efficiency

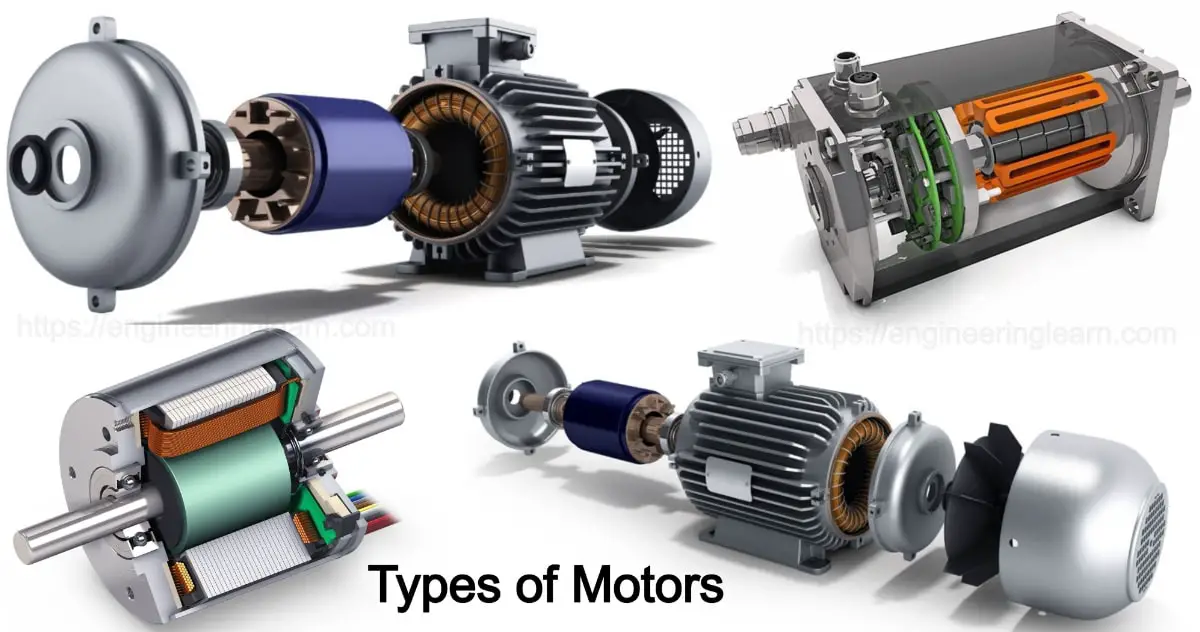

In the realm of Industrial Manufacturing, automation plays a pivotal role in streamlining various processes. Machines equipped with automation technology can perform repetitive tasks with precision and speed, saving time and resources.

Enhancing Productivity and Accuracy

One of the key benefits is the substantial improvement in productivity. Automated systems work tirelessly without breaks, ensuring continuous production. Moreover, the accuracy achieved by machines significantly reduces errors that may occur in manual processes.

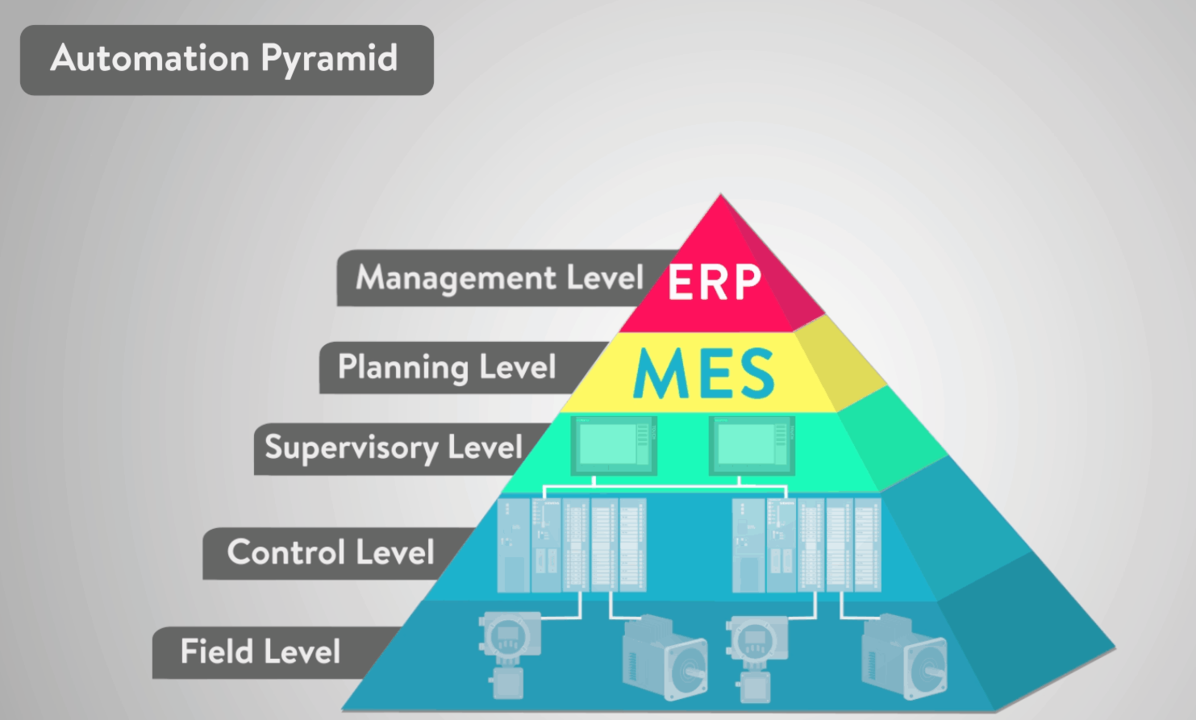

Technical Engineering Marvels in Industrial Automation

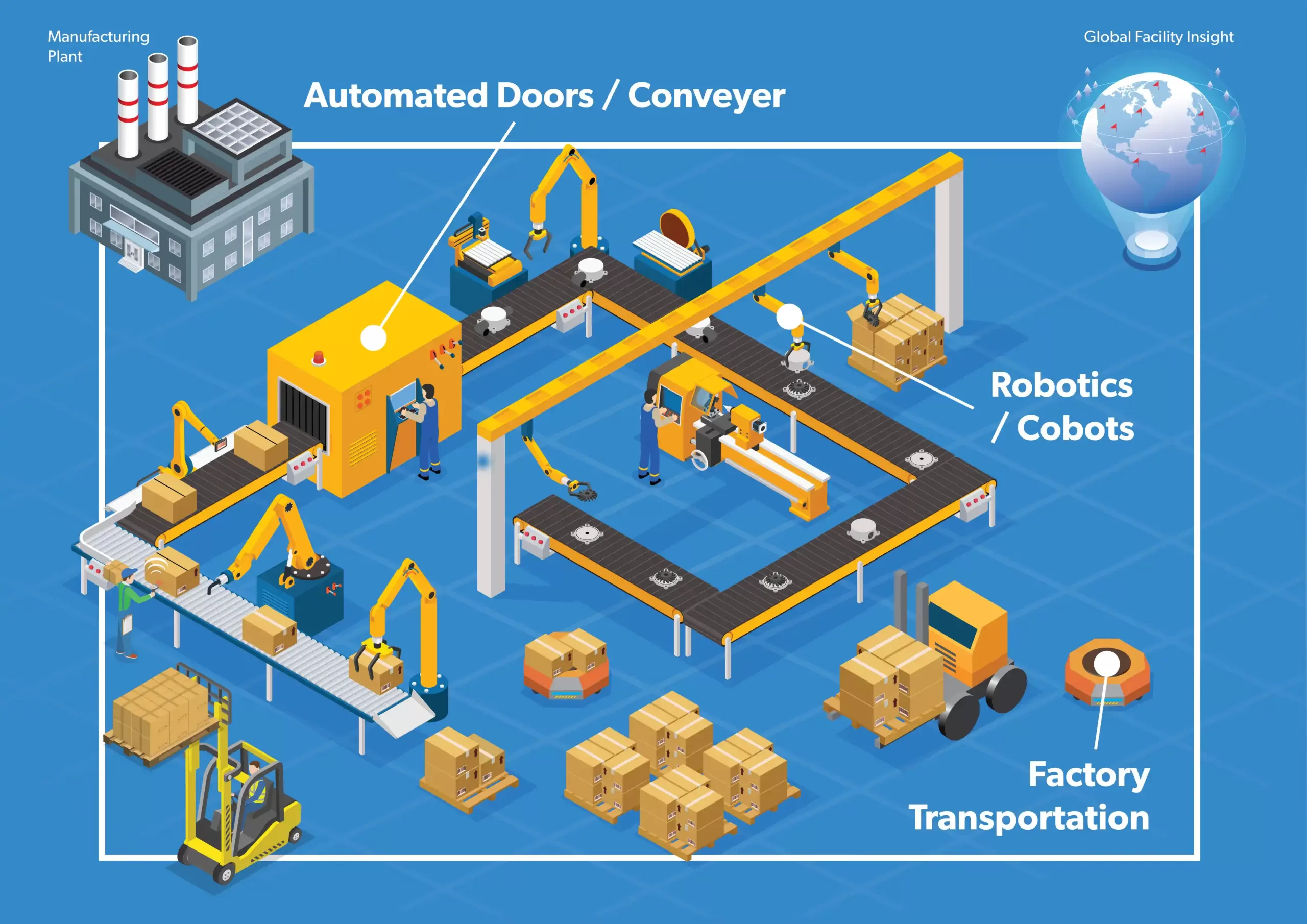

To comprehend the profound impact of Industrial Automation, let’s explore the technical engineering marvels that make it all possible.

Programmable Logic Controllers (PLCs)

In the heart of automation lies Programmable Logic Controllers (PLCs), small computers tailored for industrial applications. These devices efficiently control machinery, ensuring seamless coordination in the manufacturing process.

Sensors and Actuators

Sensors act as the eyes and ears of automated systems, detecting changes in the environment. Actuators, on the other hand, translate digital commands into physical actions, enabling machines to respond to the data collected by sensors.

Practical Applications in Manufacturing

Now, let’s take a practical look at how Industrial Automation unfolds in the manufacturing setting, bringing tangible benefits.

Increased Precision in Production through Industrial Automation

Automated machines can perform intricate tasks with precision, maintaining consistent product quality. This is particularly crucial in industries where precision is paramount, such as aerospace or medical device manufacturing.

Cost-Efficiency Through Resource Optimization

Automation minimizes the need for human intervention in routine tasks, leading to resource optimization. This translates to reduced labor costs and more efficient use of materials, contributing to overall cost-effectiveness.

The Role of Skilled SEO Experts in Industrial Automation

In our digital age, where information is at our fingertips, the role of a Skilled SEO Expert becomes crucial in showcasing the benefits of Industrial Automation.

Crafting Online Visibility

Skilled SEO Experts employ strategies to enhance the online visibility of businesses involved in Industrial Automation. Through keyword optimization and strategic content creation, they ensure that relevant information reaches the right audience.

Building Credibility in the Digital Space

In a world driven by online presence, credibility is key. SEO Experts work towards building a strong digital reputation for manufacturers engaged in Industrial Automation, establishing them as leaders in their field.

Navigating the Future with Industrial Automation

As we look ahead, the landscape of Industrial Manufacturing is set to undergo further transformations through the continued integration of automation. The journey towards a more automated future presents exciting opportunities and challenges.

Embracing Technological Advancements

Staying abreast of technological advancements is imperative for manufacturers aiming to harness the full potential of automation. Regular updates and adaptation to new technologies ensure a competitive edge in the market.

Addressing Workforce Transition

While automation brings efficiency, it also prompts a shift in the workforce landscape. Skilled technicians and engineers will play a crucial role in maintaining and troubleshooting automated systems.

Practical Application

Let’s imagine a manufacturing company that decides to implement Industrial Automation. They introduce automated robots in their assembly line to handle repetitive tasks like tightening bolts and assembling components. This practical application boosts efficiency, as the robots work non-stop without breaks, ensuring a consistent and faster production pace. This results in a significant increase in overall productivity, allowing the company to meet customer demands more effectively.

Real-world Impact

In a real-world scenario, a manufacturing plant adopts Industrial Automation to enhance safety. By integrating automated systems in hazardous tasks, such as handling toxic substances, the risk to human workers is minimized. This not only ensures a safer working environment but also reduces the number of workplace accidents. The real-world impact is the improved well-being of workers and a positive shift towards sustainable and responsible manufacturing practices.

“Implementing automation in manufacturing isn’t just about machines; it’s a transformative journey towards efficiency and progress.”

Conclusion: Embracing the Future of Manufacturing

In conclusion, Industrial Automation is not just a technological advancement; it’s a transformative force shaping the future of manufacturing. From streamlining processes to enhancing productivity, the benefits are vast and impactful. As we navigate this evolving landscape, a collaborative effort between technical engineers and SEO experts will pave the way for a successful transition into the automated future of Industrial Manufacturing.