In the vast landscape of industrial manufacturing, Electrical Relay Controls emerge as silent conductors orchestrating the intricate symphony of machinery. In this exploration, let’s unravel the essence of Electrical Relay Controls and their pivotal role in the realm of industrial manufacturing, breaking down complex notions into digestible concepts.

“In the world of manufacturing, Electrical Relay Controls are the unsung conductors, orchestrating the symphony of machines.”

Decoding Electrical Relays

To simplify, electrical relays act as traffic controllers for machines. Much like a vigilant traffic officer, they govern the flow of electricity, deciding when to allow it to pass and when to bring it to a halt. These relays function as intelligent switches, contributing to the automation of various tasks within industrial setups.

Significance in Manufacturing Dynamics

In the heart of industrial manufacturing, where the rhythmic hum of machines propels production, Electrical Relay Controls function as the nerve center. Their primary task is to facilitate automation, ensuring that diverse components collaborate seamlessly. This not only heightens operational efficiency but also minimizes the likelihood of errors in the manufacturing process.

Operational Mechanism

At its core, an electrical relay responds to a signal by either opening or closing a circuit. It operates as a messenger, attentively awaiting instructions and executing tasks accordingly. This straightforward on-off mechanism forms the foundation of the automation that characterizes modern manufacturing.

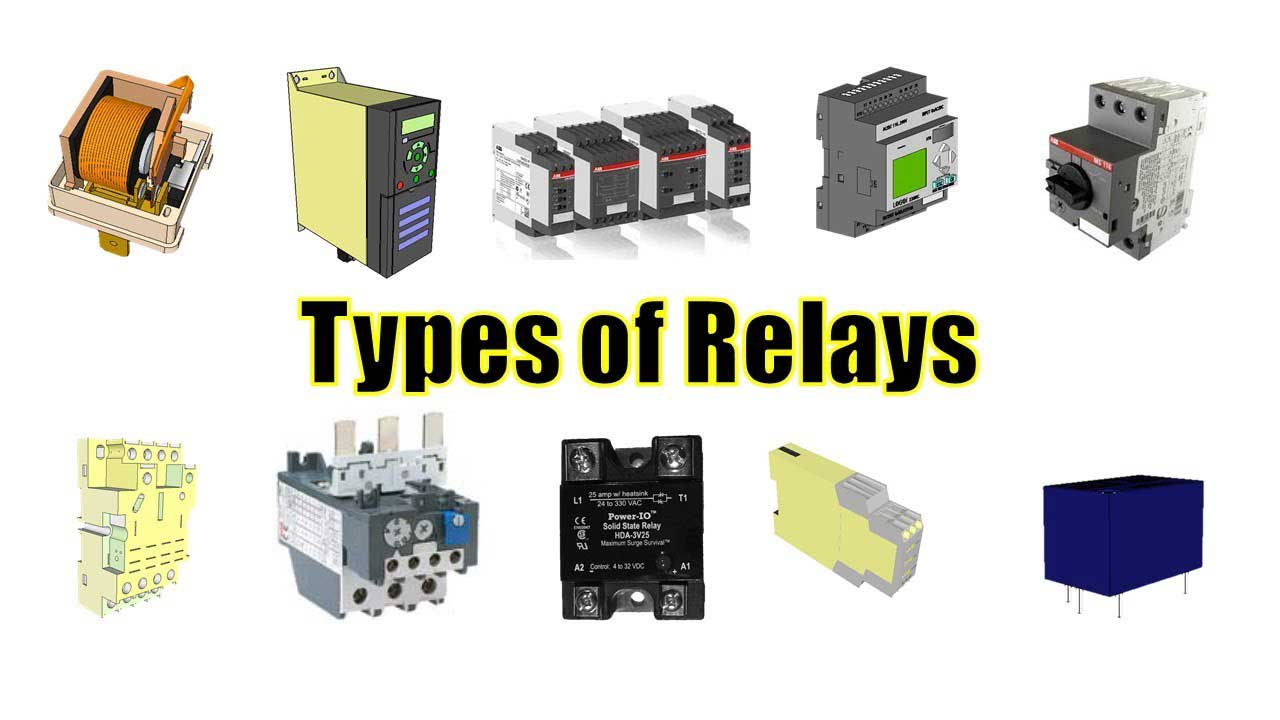

Diverse Types of Electrical Relays

- Electromagnetic Relays

- Utilizing magnets to manipulate circuits, these relays operate with a magnetic finesse.

- Analogous to a magnetic handshake, attracting and releasing to regulate the flow of electricity.

- Solid State Relays

- Distinguished by their absence of moving parts, solid-state relays employ semiconductor devices for switching.

- Comparable to a sophisticated gatekeeper, they manage electrical flow with precision, sans mechanical components.

Applications Across Industrial Sectors

- Machine Control

- Electrical Relays function as the guiding force behind the commencement and cessation of machines.

- Imaginatively akin to a conductor orchestrating an ensemble, ensuring each component harmonizes to create a seamless production.

- Temperature Control

- They play a pivotal role in maintaining optimal temperatures within industrial processes.

- Picture a thermostat in a home, extrapolated to an industrial scale, diligently preventing extremes of heat or cold.

- Safety Systems

- Acting as vigilant guardians, Electrical Relays promptly shut down systems in the presence of abnormalities.

- Comparable to a watchful security guard, their role extends to ensuring the safety of both machines and the personnel working in proximity.

Addressing Challenges and Embracing Innovations

In the trajectory of progress, challenges inevitably surface. Traditional relays often encounter wear and tear due to moving parts. However, the landscape of innovation responds with the advent of solid-state relays, addressing durability concerns. These contemporary relays not only boast prolonged lifespans but also operate silently, contributing to a quieter and smoother industrial milieu.

Anticipating the Future of Electrical Relay Controls

Looking ahead, the horizon of possibilities beckons. With technological strides, we anticipate the evolution of even smarter and more efficient Electrical Relay Controls. The integration with the Internet of Things (IoT) looms large, promising heightened connectivity and real-time monitoring, thereby elevating control and maintenance to unprecedented levels.

Practical Application

Let’s imagine a busy manufacturing plant where Electrical Relay Controls are like traffic signals for machines. In a practical scenario, these relays ensure that each machine operates precisely when needed. For instance, in an automated assembly line, the relay receives a signal to start a particular machine, allowing it to perform its designated task. Once the task is completed, the relay receives another signal to stop the machine, maintaining a seamless and efficient production process.

Real-world Impact

Consider a scenario in an automotive manufacturing plant. If Electrical Relay Controls fail to operate effectively, it could lead to chaos on the production line. Machines might start or stop unexpectedly, causing disruptions and potentially damaging products. This real-world impact emphasizes the critical role of relays in maintaining the order and reliability of industrial processes, showcasing their significance in preventing costly disruptions and ensuring the consistent quality of manufactured goods.

“The real-world impact of a well-functioning relay is evident in the seamless and reliable operation of industrial processes.”

In Conclusion

In summation, Electrical Relay Controls emerge as unsung heroes in the narrative of industrial manufacturing. They untangle the intricacies of electrical processes, ensuring the seamless collaboration of machines. From the rhythmic cadence of a production line to the precise regulation of temperatures, relays function as behind-the-scenes maestros. As technology advances, so do these controls, heralding a future where efficiency and precision in the realm of industrial manufacturing reach new zeniths.

Relay and Relay Board

Thermal Relay

Electrical