Electric motors play a major role in the heart of industrial manufacturing, powering a wide array of machinery. Let’s delve into the world of electric motors in the simplest terms possible, exploring their types and applications.

“Electric motors are the silent heroes, powering the heartbeat of industrial manufacturing.”

Understanding the Basics

Electric motors are like magic machines that turn electricity into motion. They’re the unsung heroes behind the scenes, making things move in factories and industries. These motors are everywhere, from conveyor belts to assembly lines, quietly working to keep things in motion.

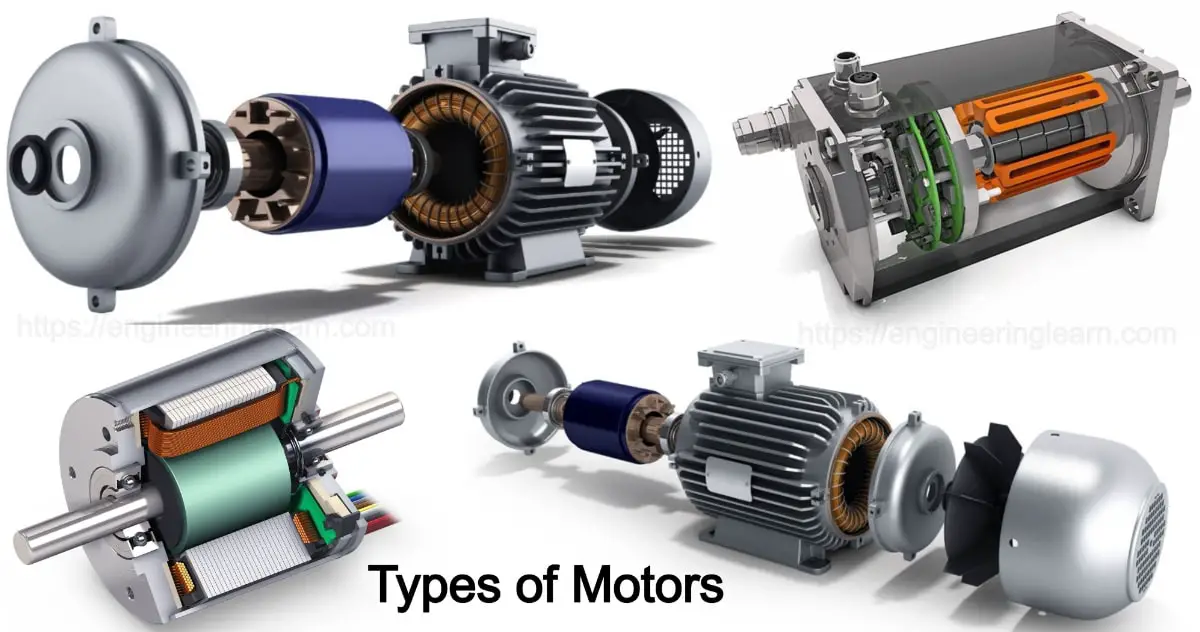

The Mighty Types of Electric Motors

1. AC Motors

AC motors, or alternating current motors, are like the swiss army knives of the motor world. They’re versatile and handle a variety of tasks, from pumping water to spinning fans. In factories, you’ll find AC motors buzzing away, making sure processes run smoothly.

2. DC Motors

Direct current motors, or DC motors, are simple yet powerful. Think of them as the sprinters of the motor family. They provide a quick burst of energy, making them perfect for applications where speed matters, such as in small tools and appliances.

3. Servo Motors

Servo motors are the precision artists. They’re like the painters of the motor world, carefully controlling movement and position. Industries use them in robotics and machinery where accuracy is non-negotiable.

4. Stepper Motors

Stepper motors are the master choreographers. They move in precise steps, making them ideal for tasks that require controlled and precise rotation, like in 3D printers and CNC machines.

The Dance of Industrial Manufacturing

In the realm of industrial manufacturing, electric motors take center stage, performing a dance of productivity. Let’s explore how these motors contribute to the manufacturing process.

Driving Conveyor Belts

Picture a busy factory with goods moving seamlessly along conveyor belts. AC motors power these belts, ensuring a smooth flow of products from one station to another. It’s like a well-coordinated dance where each step is powered by electricity.

Powering Machines

In the heart of manufacturing plants, various machines hum with the energy of electric motors. DC motors give the necessary push for tools and machines, contributing to the overall efficiency of the manufacturing process.

Controlling Robotic Arms

In the modern era of automation, robotic arms powered by servo motors take the stage. These arms delicately handle tasks that require precision, such as assembling intricate components. It’s like a ballet of machinery, choreographed by the gentle movements of servo motors.

Ensuring Precision in 3D Printing

Stepper motors shine in the world of 3D printing, where layers upon layers of material come together to create intricate designs. The controlled steps of stepper motors ensure that each layer is laid down with precision, resulting in flawless 3D prints.

The Importance of Electric Motors in Industrial Manufacturing

In the grand performance of industrial manufacturing, electric motors are the stars that ensure the show goes on without a hitch. Their reliability, versatility, and precision make them indispensable in various processes.

As technology advances, electric motors continue to evolve, bringing new levels of efficiency and sustainability to industrial manufacturing. The future holds exciting possibilities, with motors becoming smarter, more energy-efficient, and playing an even more significant role in shaping the manufacturing landscape.

Practical Application

Let’s imagine a factory using electric motors in their assembly line. The practical application comes to life as AC motors smoothly operate conveyor belts, transporting products from one station to another. This efficient movement ensures a streamlined manufacturing process, enhancing productivity and reducing delays. The electric motors become the silent workforce behind the scenes, showcasing their practical application in the daily operations of the factory.

Real-world Impact

In a real-world scenario, consider a manufacturing plant that upgrades its machinery to include advanced electric motors. The impact is tangible as the production speed increases, leading to higher output and meeting market demands more effectively. This upgrade not only improves efficiency but also reduces energy consumption, aligning with sustainability goals. The real-world impact is felt in the form of a more competitive and environmentally conscious manufacturing facility.

“In embracing advanced motors, we not only boost efficiency but also pave the way for a sustainable manufacturing future.”

Conclusion

In the symphony of industrial manufacturing, electric motors provide the rhythmic beats, ensuring harmony and efficiency. Understanding the types and applications of these motors is like decoding the language of the manufacturing world. From AC motors driving conveyor belts to servo motors delicately controlling robotic arms, each type plays a crucial role.

So, the next time you witness the seamless operation of a manufacturing plant, remember that behind the scenes, electric motors are working tirelessly, turning the wheels of progress with the magic of electricity.

Motor: High Capacity 22 KW to 200 KW/ 3 Phase, ABB

Motor: High Capacity 22 KW to 200 KW/ 3 Phase, Siemens

Motors