Automation in industrial manufacturing is like having a super-smart assistant that takes care of repetitive tasks, making things faster, more efficient, and sometimes even cooler. In this article, we’re going to delve into the fantastic world of automation systems and explore the different types that make our industrial machines dance to the rhythm of progress.

“In the dance of manufacturing, industrial robots are the rock stars, flawlessly performing tasks from welding to assembling.”

What is Automation Anyway?

Before we dive into the types, let’s understand the basic dance steps of automation. Automation is like having a robot buddy that follows a set of instructions to get things done. In industrial manufacturing, this means machines doing tasks without needing a constant human push.

Now, let’s break down the dance floor into different types of automation systems that make everything groove in the realm of industrial manufacturing.

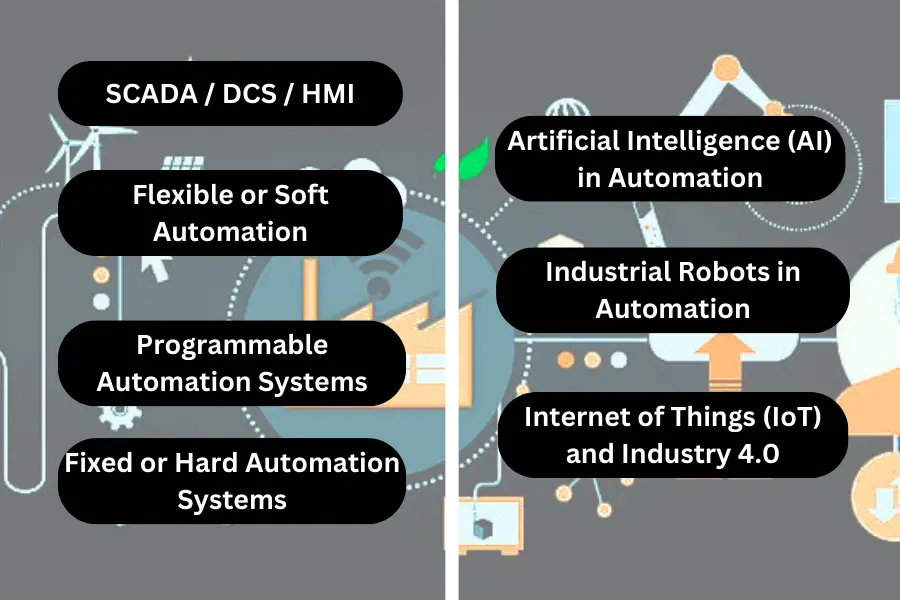

Fixed or Hard Automation Systems

Think of this as the robot that knows one dance move perfectly. Fixed automation is for tasks that don’t change much. Imagine a robot on an assembly line. It’s great at doing the same thing over and over, like putting the same part in the same place. It’s like having a dance partner who never messes up the steps.

Programmable Automation Systems

Now, imagine a dance where the moves can be changed. That’s programmable automation for you. These systems are flexible. They can be taught new dance steps, or in the industrial world, new tasks. It’s like having a dance partner who can adapt to different music genres.

Flexible or Soft Automation Systems

Taking flexibility up a notch, soft automation is like having a dance partner who can switch between salsa, hip-hop, and tango effortlessly. These systems are super adaptable, handling various tasks without needing a major overhaul. It’s like having a dance partner who can handle a variety show.

Industrial Robots – The Dance Masters

Industrial robots are the rock stars of the automation world. These are the machines that can do it all – welding, painting, assembling – you name it. They are like the performers who can dance, sing, and act, all in one show.

CNC Machines – Precision Dancers

CNC (Computer Numerical Control) machines are the precision dancers. They follow instructions to the dot, carving out intricate designs with utmost accuracy. It’s like having a dancer who can do the most intricate ballet routine flawlessly.

Automated Guided Vehicles (AGVs) – The Transport Dancers

In the industrial dance floor, materials need to move around. AGVs are the transport dancers, gracefully carrying materials from one spot to another without missing a beat. It’s like having a partner who knows when to twirl and when to take a smooth turn.

Supervisory Control and Data Acquisition (SCADA) – The Dance Choreographer

SCADA is like the choreographer who oversees the entire dance performance. It keeps an eye on all the moves, ensuring everything is in harmony. It’s the control system that keeps the dance floor organized and spectacular.

Distributed Control Systems (DCS) – Harmony Orchestra

In a big industrial dance, different sections need to move together. DCS is like the harmony orchestra, making sure all instruments play in sync. It coordinates the different sections of the manufacturing process, ensuring a symphony of efficiency.

Human-Machine Interface (HMI) – Dance Floor Interaction

Imagine a dance where you can request a move, and the dance partner responds. That’s HMI in automation. It’s the touch screen or panel where humans can interact with the machines, making the dance a collaborative effort.

PLC (Programmable Logic Controller) – Dance Routine Master

PLCs are like the dance routine master. They control the sequence of moves, ensuring everything happens in the right order. It’s the brain behind the dance routine, making sure each step is executed flawlessly.

Internet of Things (IoT) – Dance Floor Connectivity

In the modern dance of automation, IoT is the connectivity maestro. It allows different machines to talk to each other, creating a synchronized dance floor where every move is in harmony.

Artificial Intelligence (AI) – The Dance Improviser

AI takes automation to the next level. It’s like having a dance partner who not only follows the routine but also improvises based on the vibe of the crowd. In manufacturing, AI can adapt and optimize processes on the fly.

3D Printing – The Sculpture Dancer

When it comes to creating physical objects, 3D printing is the sculpture dancer. It adds layers, creating intricate designs with precision. It’s like having a partner who sculpts the dance routine into a tangible masterpiece.

Vision Systems – The Watchful Eyes

In the dance of manufacturing, vision systems are the watchful eyes. They use cameras and sensors to ensure every move is on point. It’s the technology that keeps a keen eye on the details.

Motion Control Systems – The Dance Tempo Setters

In a dance, tempo is crucial. Motion control systems set the tempo in manufacturing by regulating the speed and movement of machines. It’s like having a partner who ensures the dance is not too fast or too slow.

Practical Application:

Let’s imagine you’re running a factory where you make awesome gadgets. With fixed automation, your assembly line can consistently put together the same parts for every gadget without a hiccup. It’s like having a reliable team member who never forgets the steps, ensuring each gadget is as perfect as the last one. This means less time fixing mistakes and more time creating top-notch products. Fixed automation is your secret weapon for a smooth and efficient gadget-making dance!

Real-world Impact:

In the real world, think about a car manufacturing plant. Programmable automation allows the robots to switch tasks easily. So, if one day the plant decides to produce more electric cars instead of petrol ones, these robots can quickly learn the new dance moves. This flexibility means the plant can adapt to changing trends and demands without missing a beat. Programmable automation ensures the car factory remains a versatile dancer in the ever-evolving automotive world.

“Programmable automation is like giving our machines the ability to learn new dance moves, keeping manufacturing plants in tune with the changing times.”

Wrapping Up the Dance

In the grand ballroom of industrial manufacturing, automation systems are the dance partners that keep the rhythm alive. From fixed automation to the improvisational skills of AI, each type plays a crucial role in creating a symphony of efficiency.

So, the next time you see a product on the shelf, remember the intricate dance of automation that brought it to life. It’s a dance of precision, adaptability, and collaboration, where machines and humans waltz together in the pursuit of progress. Cheers to the dance of automation, making our lives smoother, faster, and undoubtedly more entertaining!

PLCs